Industrial Gas Springs designs and manufactures a wide range of gas spring and dampers to address our customers’ load support and motion control design problems.

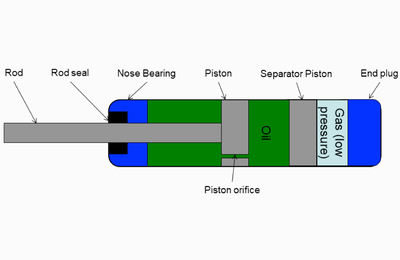

Gas springs (often called gas struts, or gas shocks) are used in a wide spectrum of industries to support constrained masses such as panels and doors, while locking gas springs provide the option to “lock” the spring at any position of its stroke. Dampers are used to control the speed of moving masses. We offer stand-alone and combination products (e.g. Damped Gas Springs and damped locking gas springs), configured to match your exact needs.

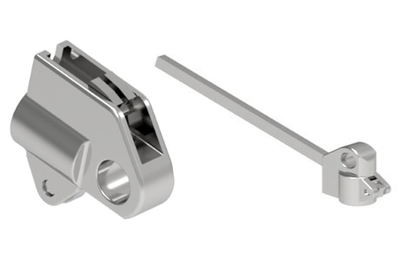

Custom features available include reduced compression ratio, high temperature seals, food grade oil fill, high speed extension and low friction, as well as custom sizes. Our line also includes mounting hardware such as end fittings, brackets, and ball studs to attach our gas springs and gas struts to your product or application.

To address customers’ urgent needs, we stock gas springs and dampers in a range of sizes, which can be adjusted to your requirements and dispatched within 24 hours.